UnSaturated Polyester Resin Kettle

Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. We offer our clients a wide range of Polyester Resin Plants. We maintain high standards in our range of products. To maintain these international quality standards, we regularly keep a stringent check on the quality of the products at varied manufacturing stages. Polyester resins are used in sheet molding compound, bulk molding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass.

(Saturated Polyester Resin Plant – Powder form)

(Saturated Polyester Resin Plant – Powder form)

(Un-Saturated Polyester Resin Plant – Liquid form)

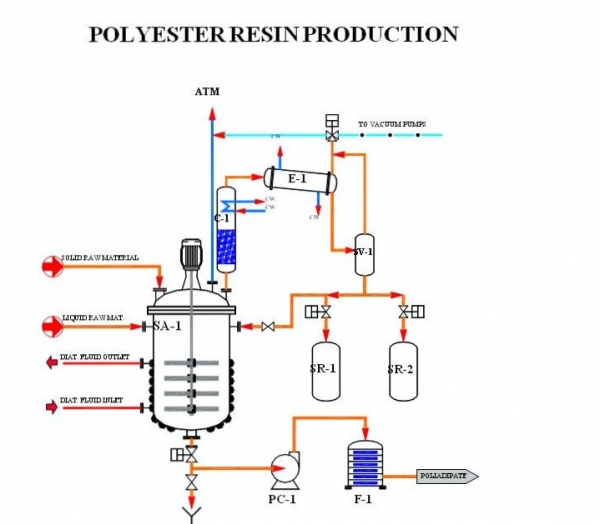

The major operations involved in the manufacture of polyester resin are esterfication and blending – which are carried in their respective kettles. The most common raw materials used are polypropylene glycol, melic anhydride and styrene monomer. In addition small quantities of inhibitors and other additives are required for the process. The process involved is poly condensation reaction and blending the polyester resin with the monomer. Due to the sensitivity of polyester resin to contamination; in the course of condensation reaction and during subsequent handling the material of construction must be carefully selected.

The esterfication reactor is changed through a manhole with required amount of glycol and the solid anhydride. The mass is heated up to 200°C under agitation and inert gas N2 is slowly applied. The partial condenser condenses the glycol but process the water to the total condenser. The esterification is continued until a predetermined acid value 10 to 15 is reached. After achieving the predetermined viscosity the heating is stopped and the batch is dropped in to the blending kettle. In the blending kettle the batch is cooled to 100 – 102°. Styrene is pumped in the blender and viscosity is adjusted until the batch attains room temperature. The batch is then pumped through Sparkler filter press in to the storage tanks.

| Usage/Application | FRP |

| Grade Standard | Chemical Grade |

| Form | Liquid |

| Capacity | 60000 |

| Automatic Grade | Automatic |

| Power Consumption | 100 KW |

| Design Type | Customized |

| Grade | SS304 |

| Material | Stainless Steel |

Minimum order quantity: 1 Unit

Unsaturated Polyester Resin Resin plants are one of the most exclusive quality products of our company which we are not only manufacturing extensively but also are supplying and providing the services for their installation in almost all the regions of the country. These chemical plants have been specially designed for the processing and manufacture of all the kinds of chemicals which are required for the use in the industrial processes. These chemical plants are used and appreciated in almost all the regions of the country and are widely in demand in several chemical and pharmaceutical industries.

Features:

- Excellent construction

- Reliable and safe utilization

- Long lasting

- Low consumption

- Low maintenance

- Easily affordable

Polyester Resin Plants Manufacturer, Saturated Polyester Resin Plant, Un-saturated Polyester Resin Plant manufacturer, Alkyd Resin Plants, Polyester Resin Plants, PVA Emulsion Resin Plant, Epoxy Resin Plants

Products

- UnSaturated Polyester Resin Kettle

- UnSaturated Polyester Resin Kettle

- Orthophthalic Unsaturated Polyester Resin Plant

- Chemical Machinery & Equipment

- Pharmaceutical Equipment

- Paint Machinery

- Resin Manufacturing Plant & Machinery

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Pvc Solvent Cement Adhesive Machine

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Sigma Mixer Kneader

- sigma mixer manufacturer india