Polyester Resin Plant Manufacturer

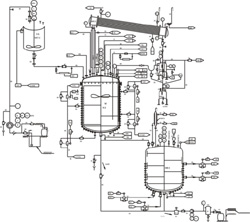

Our Polyester Resin Plant is developed and supplied as per our clients' requirements. The basic system consists of a reaction kettle, vertical column, sub-cooler, and horizontally inclined condenser with separator and dilution blender. The batch time is approximately 16 to 20 hours and therefore, suitable mechanical seal arrangement for better results and to prevent any leakage is provided.

Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. We offer our clients a wide range of Polyester Resin Plants. We maintain high standards in our range of products. To maintain these international quality standards, we regularly keep a stringent check on the quality of the products at varied manufacturing stages. Polyester resins are used in sheet molding compound, bulk molding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass.

The esterfication reactor is changed through a manhole with required amount of glycol and the solid anhydride. The mass is heated up to 200°C under agitation and inert gas N2 is slowly applied. The partial condenser condenses the glycol but process the water to the total condenser. The esterification is continued until a predetermined acid value 10 to 15 is reached. After achieving the predetermined viscosity the heating is stopped and the batch is dropped in to the blending kettle. In the blending kettle the batch is cooled to 100 – 102°. Styrene is pumped in the blender and viscosity is adjusted until the batch attains room temperature. The batch is then pumped through filter in to the storage tanks.

SPECIFICATION

| Capacity | 50 L TO 20,000 LITER |

| Machinery in Plant | Chemical Reactor , Column , Condenser , Receiver & blender |

| Reactor Type | Both Dish End , Motor and Gear box , Inside Agitator for Mixing Material , Bottom discharge connection Vertical outer heating limpet and jacketed |

| Usage/Application | Reaction , Mixing or Blending Row Material |

| Mixing Material | Chemicals / Oils / Lubricant / Liquid Syrup / Sugar Syrup / Wax Melting /Engine Oil |

| Material of Construction | Stainless Steel ,Mild Storage |

| Orientation | Vertical Orientation |

| Shape | Round |

| Tank Diameter | As Per Your Requirement |

| Electric Heater | Single Phase or Three Phase |

| Temperature Controller | Automatic or PLC Operated |

| Mixing Speed (RPM) | Variable , Speed Up And Down As Per Requirement |

| Finishing Type | Matt Type ,Mirror Finishing |

| Heating and Cooling System | YES |

| Temperatures Range | 30 TO 250 Degree |

| Vacuum | Yes |

| Cooling Coil | Internal Coil |

| Outer | Heating coil or jacket |

| Plat Foam | Mild Steel |

Application Industry

- Pharmaceutical industry

- Chemical industry

- Food and beverages industry

- Petro-chemical industry

- Resins industry

- Polymers industry

- Coatings industry

- Adhesives industry

- Agricultural industry

- General chemicals industry

- Plastics industry

- Rubber industry

- Herbal Extractor

Resin Plants Technical Parameter:

| Reaction Pot | Vertical Fractionating column | Horizontal Condenser | Separator | ||||

| Specification(L) | Size of Fractionating column(mm) | Stuff Volume (m3) |

Cooling Area (m2) |

Specification (mm) |

Condensation Area (m2) |

Specification (mm) |

Volume (L) |

| 300L | Φ159×560 | 0.01 | 0.22 | Φ219×1000 | 2.4 | Φ410×450 | 60 |

| 500L | Φ159×750 | 0.015 | 0.29 | Φ219×1500 | 3.6 | Φ410×450 | 60 |

| 1000L | Φ194×800 | 0.025 | 0.62 | Φ273×1500 | 5 | Φ410×450 | 60 |

| 1500L | Φ194×850 | 0.025 | 0.62 | Φ273×2000 | 6.5 | Φ410×450 | 60 |

| 2000L | Φ219×1000 | 0.035 | 1.0 | Φ325×2000 | 8 | Φ600×600 | 150 |

| 3000L | Φ273×1100 | 0.058 | 1.2 | Φ325×2000 | 10 | Φ600×600 | 150 |

| 5000L | Φ273×1200 | 0.065 | 1.5 | Φ377×2000 | 15 | Φ700×750 | 300 |

| 8000L | Φ325×1500 | 0.065 | 4 | Φ426×2000 | 20 | Φ700×750 | 300 |

| 10000L | Φ325×1800 | 0.07 | 5 | Φ426×3000 | 30 | Φ700×750 | 300 |

| 15000L | Φ377×1800 | 0.08 | 6 | Φ450×3000 | 40 | Φ800×750 | 500 |

| 20000L | Φ377×1800 | 0.08 | 6 | Φ450×3000 | 50 | Φ800×750 | 500 |

| 25000L | Φ377×2000 | 0.12 | 10 | Φ455×3000 | 60 | Φ800×750 | 500 |

| 30000L | Φ377×2000 | 0.12 | 10 | Φ475×3000 | 80 | Φ800×750 | 500 |