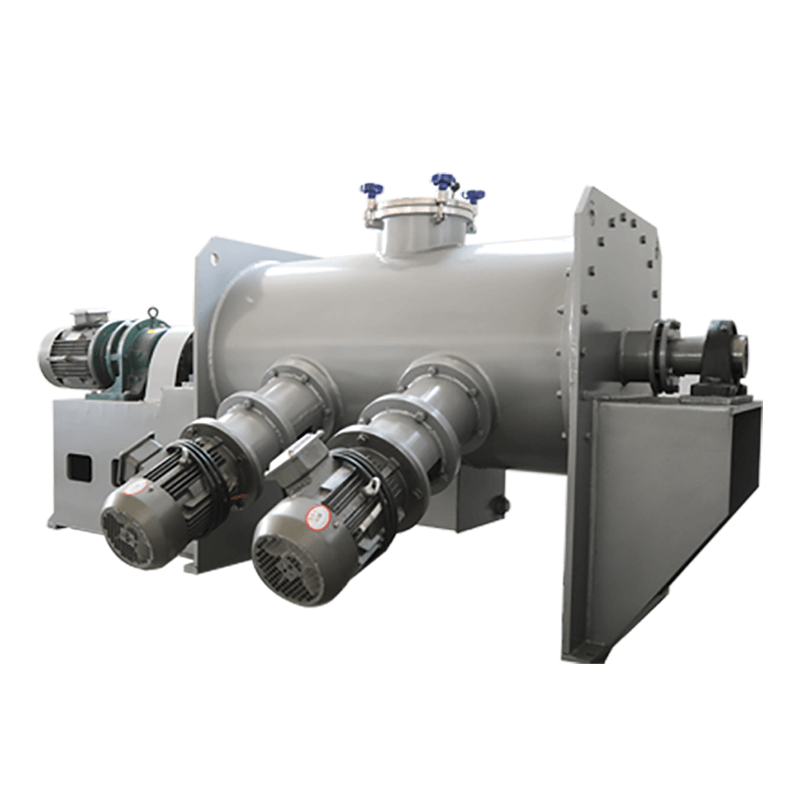

Ribbon Blender Mixer

Ribbon blenders are widely used for homogeneous mixing of dry granules & powders. The blender comprises a 'U' shaft with two sets of spiral ribbons, one inside the other. Inner and outer ribbons are perfectly arranged, that during rotation, the material reaches each corner of the trough and imparts radial & linear motion to the whole of the material to be mixed. Our range of ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending.

Ribbon blenders are widely used for homogeneous mixing of dry granules & powders. The blender comprises a 'U' shaft with two sets of spiral ribbons, one inside the other. Inner and outer ribbons are perfectly arranged, that during rotation, the material reaches each corner of the trough and imparts radial & linear motion to the whole of the material to be mixed. Our range of ribbon blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending.

Working Principle of Ribbon Blender:

Ribbon Blender (also named ribbon mixer) is a basic industrial mixing machine. They consist, basically, of a trough-shaped shell (usually 2 to 3 times longer than it is wide) with a semicircular bottom, fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades, paddles or helical screws set at a fairly close clearance to the semicircular mixer body so that no layer of material remains on the bottom of the ribbon mixer. The most effective design of ribbon layout is the double spiral in which the outer ribbon moves the product in one direction and the inner ribbon moves it in the opposite direction.

The ribbons rotate and move materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 70% of the rated capacity of ribbon blender.

Ribbon Blender Operations:

- The complete assembly is mounted on a MS/ SS structure

- The material is moved from side of the trough to the centre and vice versa resulting in quick & homogeneous mixing

- Double ribbon configuration also brings material towards central bottom outlet while discharging

- A specially designed valve is provided at the center or butterfly valve for discharge

- Blending is achieved in semi-fluidized state in the upper zone of the trough when used for fine powders

- Machine can be provided with spray nozzles with pressure spraying system for spraying additives in blenders

- Ribbon blender can also be used as dryer by providing jacket on the trough

- All contact parts in SS 304/ SS 316 quality

- Ribbon Blender Mixer comes in Standard and GMP models specially designed flush type outlet valve or butterfly valve (optional)

- Top cover with acrylic sheet

- we are also manufacturing Protein Powder Ribbon Blender for nutraceutical

Applications of Ribbon Blender Mixer

Ribbon Blender can be use for wide array of application span over pharmaceuticals, cosmetics, bulk ingredients, food preservatives, specialty chemical, beverages and lot more. Below are some of the major applications of the equipment:

Pharmaceuticals Application: Bulk Drugs, API and Nutraceuticals

Cosmetics Application:Talcum Powder, Eye shadow, Face powders, Laundry detergents

Chemicals Application: Dyes, Intermediates, Pigments, Pesticides, Fine Chemicals, Rubber Chemicals, Abrasives, Engineered plastic resins, Epoxy resins, Carbon black, Fire retardants, Polyethylene, Chemicals, Gypsum, PVC compounding, Cleaning compounds, Plastic powders

Food Appliactions:Infant formula, Cocoa mix, Instant salad dressing, Cake mixes, Seasonings, Flavorings, Gelatin, Milk Powder, Pet foods, Bakery premixes, Cake mixes, Instant breakfast cereals, Spice blends, Dietary supplements, Instant drink blends, Spices, Dried food products

Agrculture Application: Insecticides, Pesticides, Fertilizers, Pesticides and herbicides, Bird seeds

Other Applications: Handling large Dry and wet powder volume, Crystalline products, Low-viscosity paste and liquid in chemicals

Ribbon Blender Capacity Table

| Model | Gross Volume approx. | Working Volume approx. | Power |

| RM-10 | 10 Liters | 5 Liters | 0.5 H.P. |

| RM-50 | 50 Liters | 20 Liters | 1 H.P. |

| RM-75 | 75 Liters | 50 Liters | 1 H.P. |

| RM-150 | 150 Liters | 100 Liters | 2 H.P. |

| RM-250 | 250 Liters | 150 Liters | 3 H.P. |

| RM-450 | 450 Liters | 300 Liters | 5 H.P. |

| RM-600 | 600 Liters | 450 Liters | 7.5 H.P. |

| RM-1100 | 1100 Liters | 750 Liters | 10 H.P. |

| RM-1500 | 1500 Liters | 1000 Liters | 12.5 H.P. |

| RM-2000 | 2000 Liters | 1250 Liters | 15 H.P. |

| RM-3000 | 3000 Liters | 1875 Liters | 20 H.P. |

| RM-5000 | 5000 Liters | 3000 Liters | 25 H.P. |

| RM-10000 | 10000 Liters | 6000 Liters | 40 H.P. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.

FAQ:

Q: What information is needed in order to get a quote?

A: Our Horizontal Ribbon Blender is customized. The following information is needed to work out a detailed quote:

1) What raw materials you are going to mix. Raw material sample might be needed for trial production or tests;

2) Raw material bulk density and particle size

3) Load capacity in kg/batch or L/batch

4) Power supply type: 220V/380V/415V/440V, 50/60Hz, Single/three phase

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box;

Q: What kind of after-sale service can you provide?

A: 1)All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.

Related Searches

mini ribbon blender, mixing tank manufacturers, alkyd resin manufacturers in gujarat, reactor manufacturer in india, ball mill ahmedabad, bead mill machine, beads market in ahmedabad, sand mill manufacturers in ahmedabad, chemical machinery manufacturers

Products

- ETO Sterilizer Machine

- Membrane Filter Holder

- Chemical Machinery & Equipment

- Pharmaceutical Equipment

- Paint Machinery

- Resin Manufacturing Plant & Machinery

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Pvc Solvent Cement Adhesive Machine

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Sigma Mixer Kneader

- sigma mixer manufacturer india

- Syrup Manuacturing Plant manufacturer

- Pickle Mixing Machine

- Pickle Mixing Achar Mixing Machine

- Protein Powder Ribbon Blender