Lab Sigma Mixer

Description

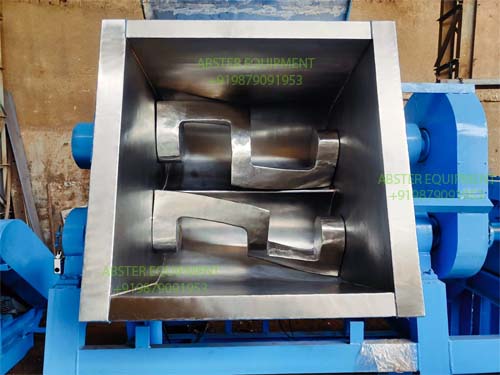

Lab Sigma Mixer is compact model mixer suitable for small batches production having usage in research labs, institutes. Machine also uses in industrial application where high value products to be processed in small batches. Machine completely manufactured from Stainless Steel 316 materials with sturdy structure. We manufacture Lab Sigma Mixer in capacity ranging from 5 kgs. Up to 50 kgs.Lab Sigma Mixer is widely uses for mixing dough, acid slurry mass, plastisizer etc.

- Made from Stainless Steel 316 materials.

- Mache polish to mirror type finish.

- Discharge option of hand wheel operated (manual) or hydraulic operated (automatic) offered.

- Jacket for heating or cooling application can be offered.

- Mineral wool insulation with cladding on jacket.

- Tangential designed ‘Z’ blades offered for uniform mixing.

- PTFE made shaft sealing provided for food grade compatibility.

- Minimum gap between trough inner shell & blades remove possibility of sticking product.

- On demand Spray system, vacuum system

- Liquid Spray System

- Vacuum System

- Blades Cooling Arrangement

- Screw System

- Automatic Valve Discharge System

Lab Sigma Mixer Salient Features

Optional Features/Accessories

Sigma Mixer Technical Specification

| Models | Working Capacity | Gross Capacity | General |

| ABFSM – 10 | 10 Liters | 16 Liters | 1.5 H.P. |

| ABFSM – 15 | 15 Liters | 24 Liters | 1.5 H.P. |

| ABFSM – 20 | 20 Liters | 32 Liters | 2 H.P. |

| ABFSM – 30 | 30 Liters | 48 Liters | 3 H.P. |

| ABFSM – 50 | 50 Liters | 80 Liters | 5 H.P. |

2L, 5L, 10L Lab Kneader Lab Sigma Mixer

sigma mixer/Z blades mixer/kneading machine/sigma kneader with double Z/Sigma Blades, is to be used for mixing and kneading of low-to high-viscosity products in many industries such as BMC/DMC, Chewing gum, candy/sugar paste, plasticize/silly putty, Hot melt adhesive , silicon compound, CMC/Cellulose, Electrode paste, carbon, pencil leads, soap, pigments, inks, plastic ect.

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.

Products

- Lab Sigma Mixer

- Reaction Vessel

- V Cone Blender Mixer

- Condenser / Heat Exchanger

- Pressure Vessels

- Distillation Unit

- Pilot Reaction Unit

- Sigma Mixer

- Ribbon Blender

- Tray Dryer

- ETO Sterilizer Machine

- Pressure Nutsche Filter(PNF)

- Membrane Filter Holder

- Ethylene Oxide Sterilizer

- Attritor Mill

- Bead Mill

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Sigma Mixer Kneader

- sigma mixer manufacturer india

Pharma process Equipment

- Pharmacutical Equipment

- Pharma Manufacturing Preocess

- Ointment Manufacturing Plant

- Syrup manufacturing Plant