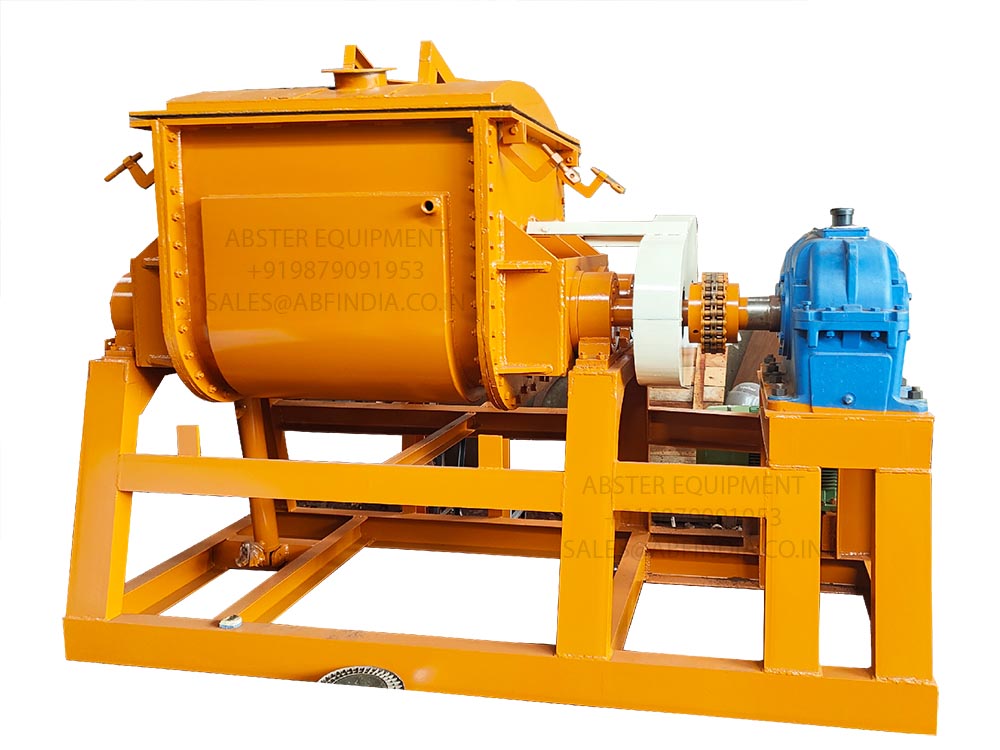

Double Sigma Arm Mixer Machine

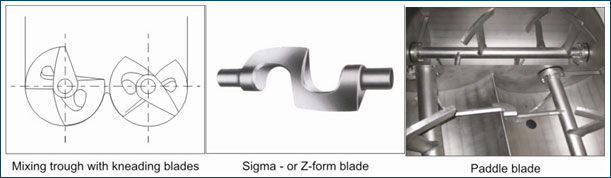

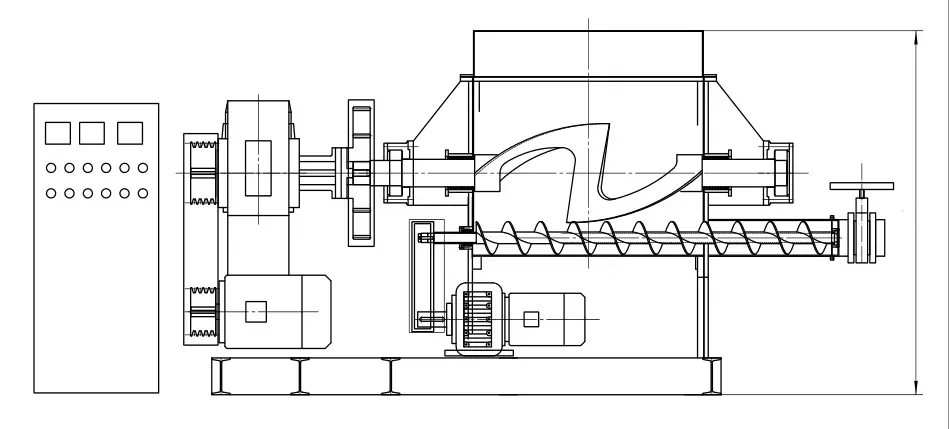

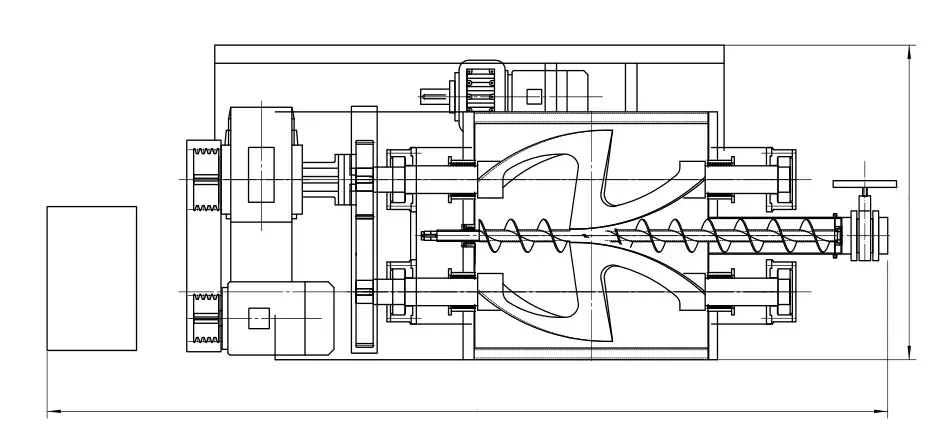

Double Sigma arm mixer is an widely used mixing machine ,with strong mixing blade and motor ,mainly for high viscous materials and slurries, It with special Z blade ,and a U shape chamber with cover , Two blade rotating with different speed ,one is slow and one is quick .two speed producing an high forced power to the materials to make the materials well mixed and stable uniformed